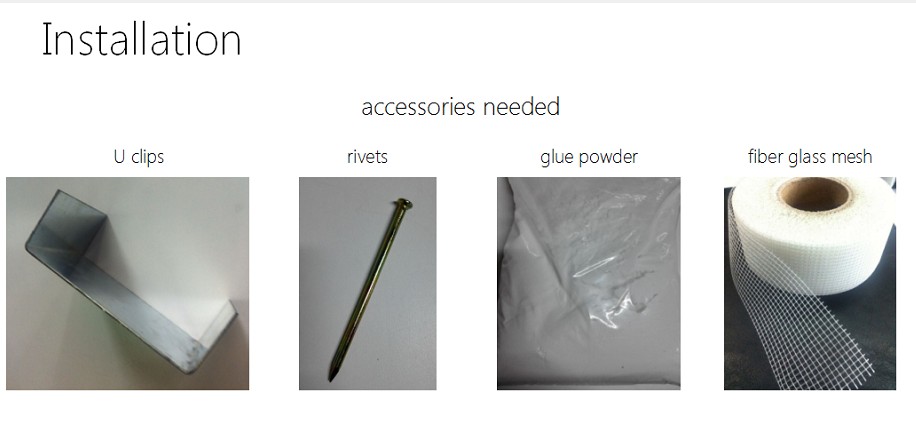

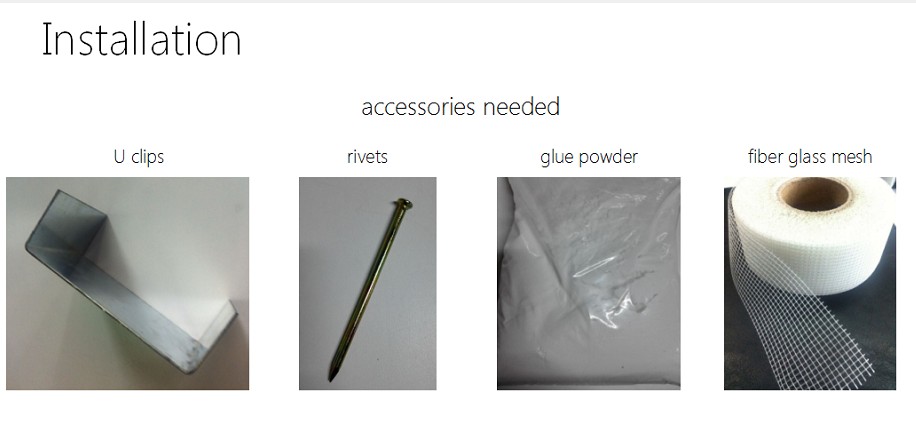

I. Installation tools: portable electric cutting saw, crowbar with cross

angle iron, rubber hand hammer, cutting machine,

chisel, plane, float, putty knife, mortar board,

broom, small iron drum, small iron shovel, 2m

long or aluminum alloy 70(90) webbing, sinker.

II. Junction materials: binding agent, saw dust, dry wood block, sand

passed 1.0mm sieve, thick sand, mazding, No107

glue,425# cement, 50mm long fiber glass, wood

dust.

Binding agent: 1) the same material with the partition panel

Or

2) 250# cement mortar and with 5cm fiberglass

Or

3) 801# glue

III.Worker team: 3person/team

IV. Installation:

1. Line the position of door and window and other points on the ground

or roof of the building according to the construction drawing. the

vertical deviation should be within 3mm, and the planeness deviation

should be within 5mm.

2. According to the size and quantity of partition panels required in

different layers to transport the panels, then use portable electric

cutting saw to cut the panels, and then making the installation.

3. Cutting the partition panel according the exact size on site. Cutting the

two side faces into serration in order to connect much more with the

partition panels.

4. During installation, one person use a crowbar with cross angle iron to

prize the partition panel, other one or two person hold the partition

panel and see the line, make the partition panels be closed and check

the verticality, after that, foist the wooden wedge to make the partition

panel be stable temporally, then draw out the crowbar.

5. Fill the junction material two times. Firstly, fill half of the junction

with the material to make the partition wall more stable, after the

solidification, continue filling the left half junction secondly.

6. Stick the fiberglass tape on the junction surface, and then brush the

liquid junction material to make the fiberglass tape cling the partition

panel closely.

V. Technical impotents:

1. The combination between partition panels. The junction between

the panels should not be smaller than 10mm to facilitate the

binding agent joint, and ensure the combination in good condition.

The maintain period is 3 days for the joints.

2. After finished the installation of the partition panels, the lights,

telephone and TV cable can be installed in the hollow part

according to the different requirements. You should firstly use

cutting machine to cut the installation area on the panels before

install the switch, socket and embedded parts.

3. You can use different carpenter screws to fix the goods on the

surface of panel, and mazding can also be used on the keel to fix

the goods。But for heavy equipments such as electric water heater,

basin, you should cut the whole on the panel and install the

embedded parts inside to used as the load bearing parts special for

the heavy electricity and so on.

4. Normal installation for the partition panel is within 3 meter high,

and not for loading bearing internal wall, concrete structure or steel

structure above and under, or with other depending beam, and the

span is within 5meter.

5. The iron materials used in installation should with antirust paint.

6. There are male and female sides for connection between the

partition panels, the vertical distance not beyond 650mm.

7. If the junction material is the same with the partition panel, the

junction material should be made on site. and must be used out in

limited period. The binding material is gruel for first time to ensure

the adherence. Filling junction within one time is forbidden. The

junction material should be not higher than the panel surface.

8. The temporary fixing material should be chosen according to the

different temperature. The type “L” steel clip is suitable for the

area with big different temperature and the dry wood wedge is

suitable for the area with small different temperature.

9. The hole for windows and doors should use amending materials

two times, between 1.5mm~3.0mm thick.

10. According to the requirements of Party A in contract or the

requirements of the drawing to find the installation position, the

difference of verticality should be within 3mm, and planeness

within 5mm.

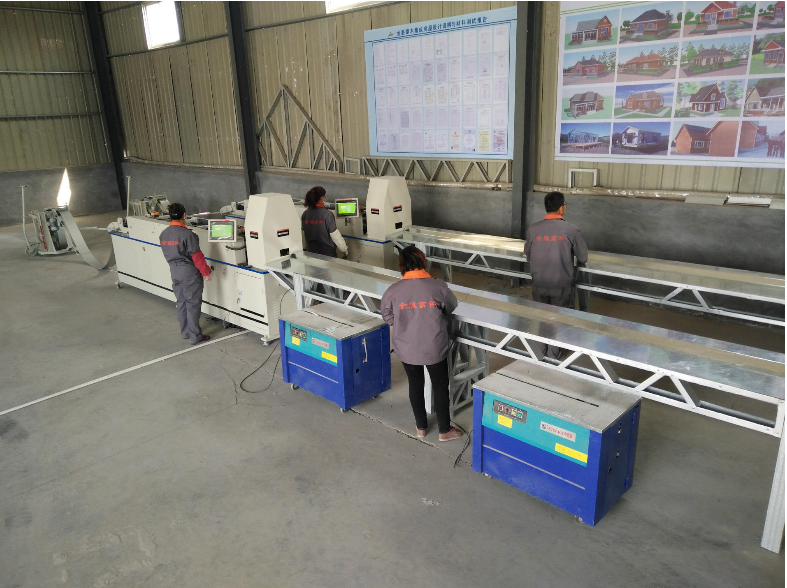

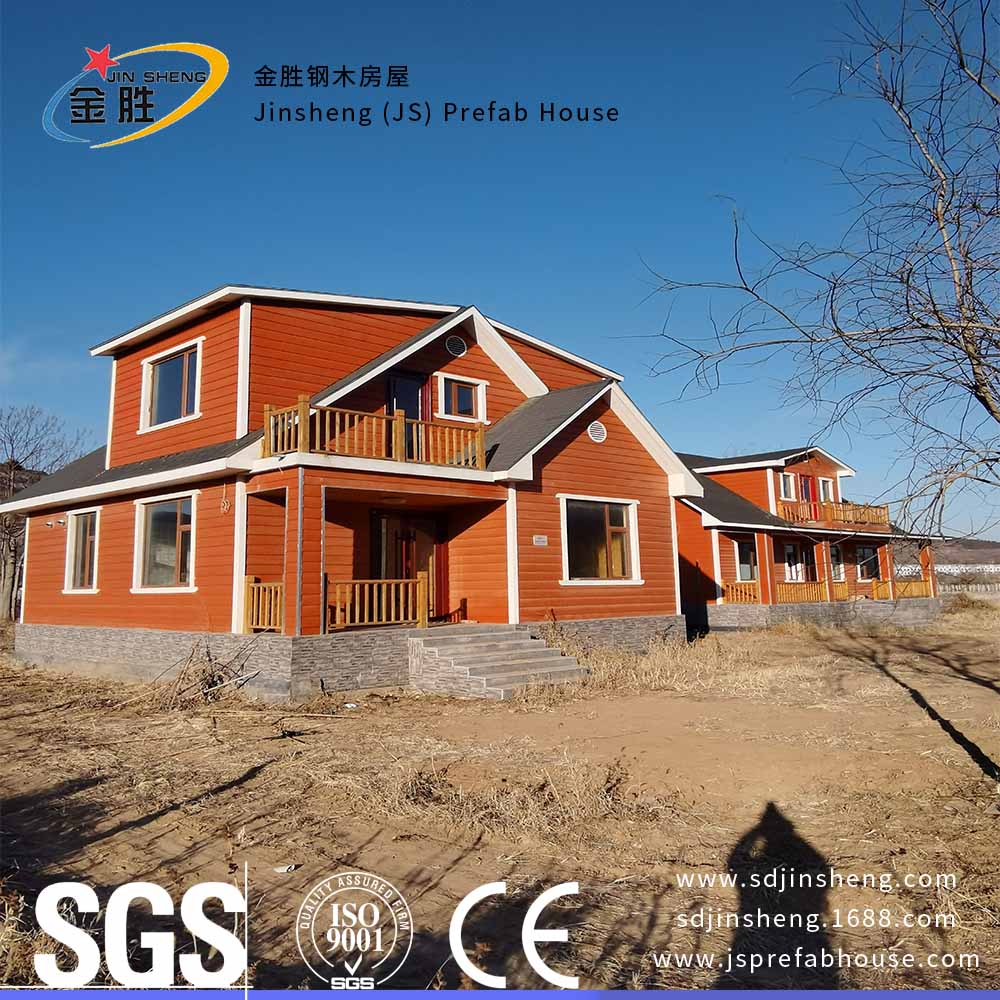

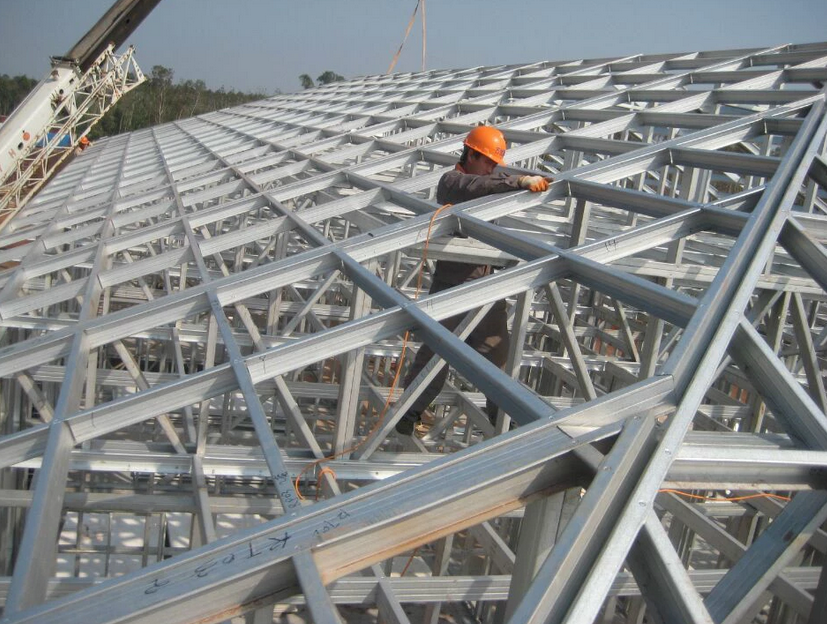

Components of a prefab house are

manufactured in an off-site industrial facility.

Components of a prefab house are

manufactured in an off-site industrial facility.