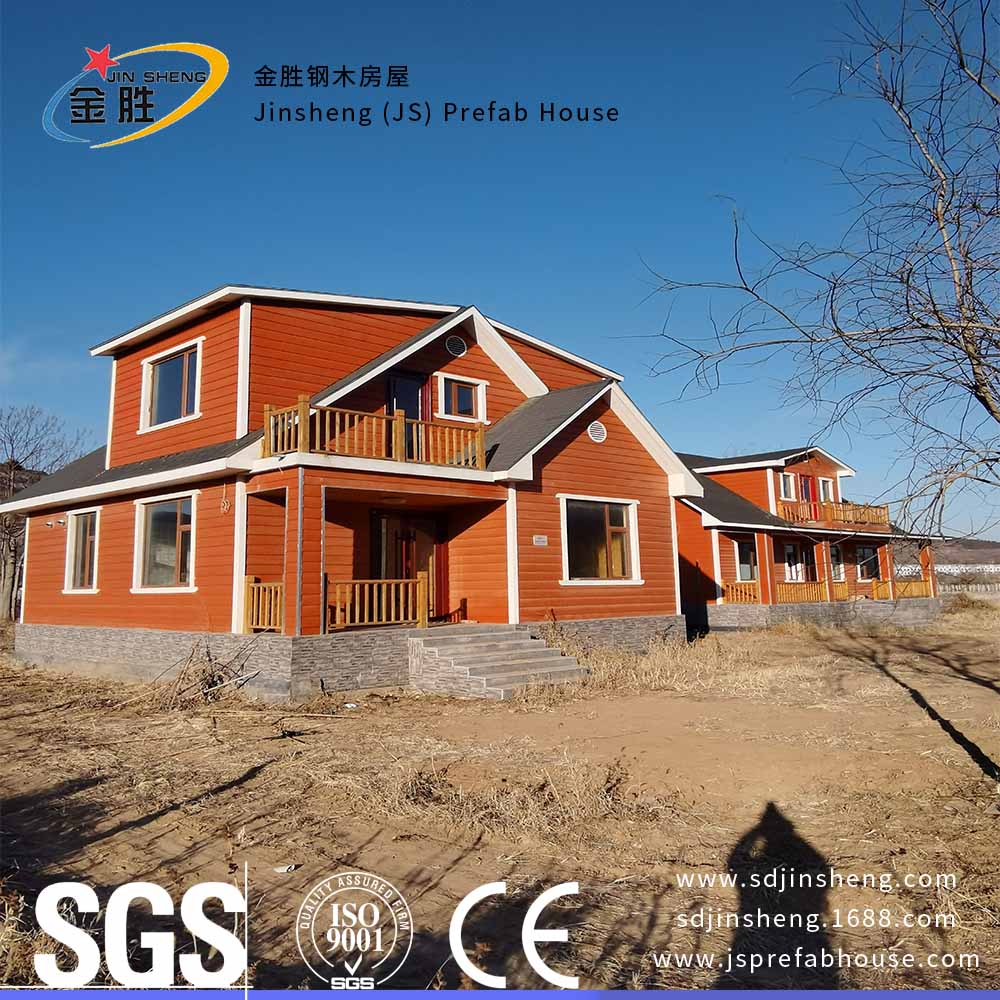

Jinsheng patent technology Reactive Powder Concrete (RPC) cover plate railway pavement

Quick detail:

Reactive Powder

Concrete (RPC) cover plate railway pavement

|

Materials

|

RPC high strength powder concrete

|

Compressive resistant

|

>130 Mpa

|

|

Fire resistant

|

GB8524 Grade A

|

Color

|

Deep grey

|

|

Experience

|

Solid board

|

Usage

|

Cover plate for railway footpath /cable

tunnel or for floor backer board

|

|

Flexural resistant

|

>18MPa

|

Permeability resistance

|

>P50

|

|

Modulus of elasticity

|

Ec>48GPa

|

28d Carbonization depth

|

0mm

|

|

Sound

insulation

|

40mm thickness 38dB

|

Size

|

L: 400-1500mm

W: 500mm

T: 25mm/35mm/40mm

|

|

Compressive resistant

|

130-400MPa

|

Density

|

2400kgs/m³

|

|

Water content

|

≤10

|

Flexural resistant

|

30-40Mpa

|

|

Modulus

of elasticity

|

>48MΩ

|

Freeze thaw resistance

|

600 times no change, 800 times loss 3.9%

modulus elasticity but shape no change

|

Production principle:

After high strength and high performance

concrete developed in building materials, people didn’t satisfied, in 1990s, they

developed a new super high strength, durable, high toughness and steady concrete,

which is mixed by DSP materials and fiber enhanced materials.

Jinsheng researched this technology, and

manufactured our own RPC formula and production technology, with our own

patent. We use Super high strength cement, quartz flour, SiO2, Carbon/copper plating

steel fiber, and other materials, through our automatic production line, and

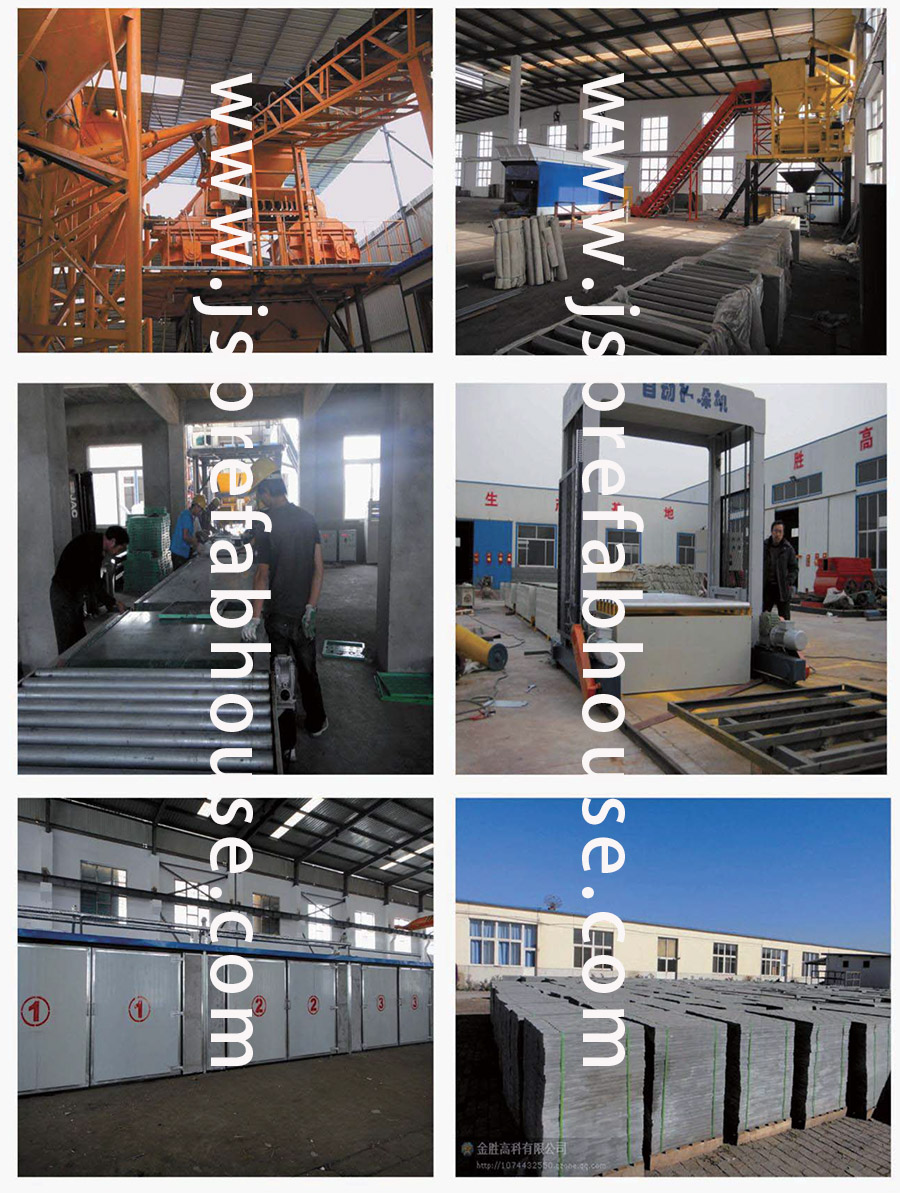

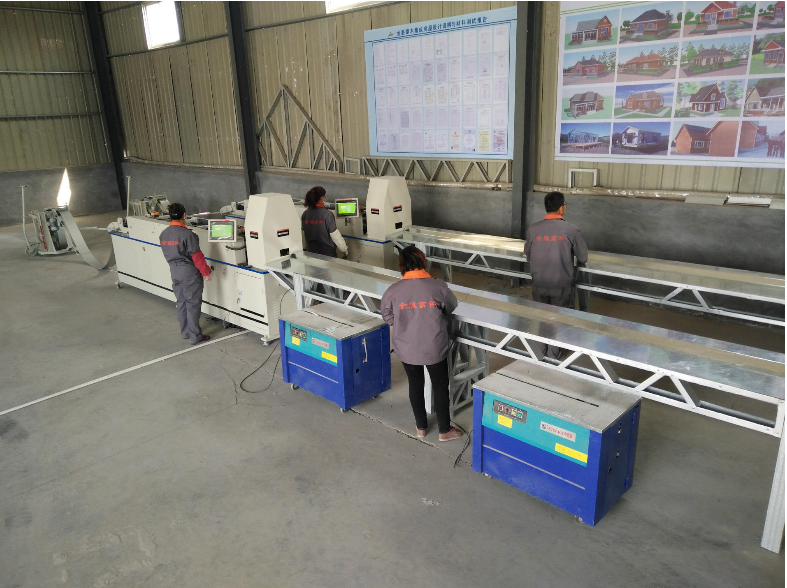

serious management for raw materials and production.

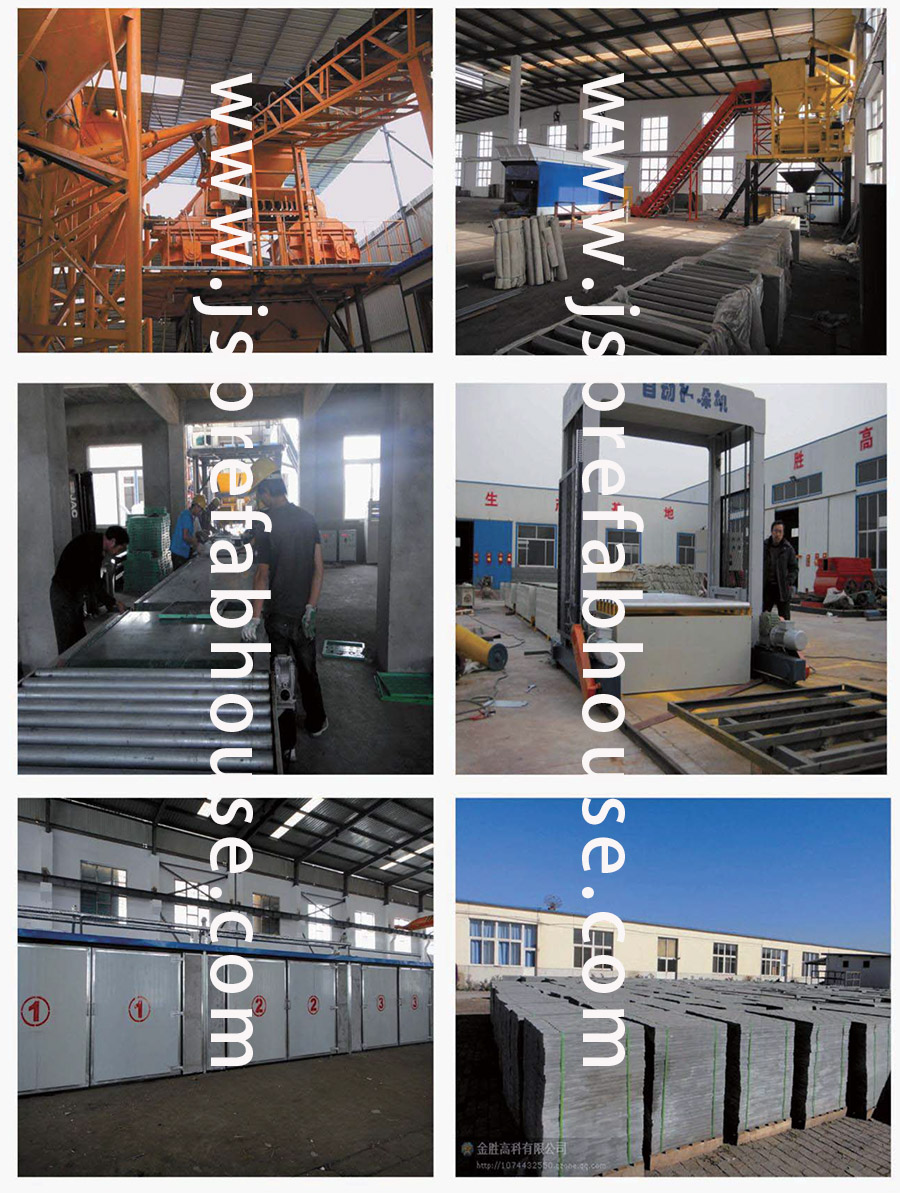

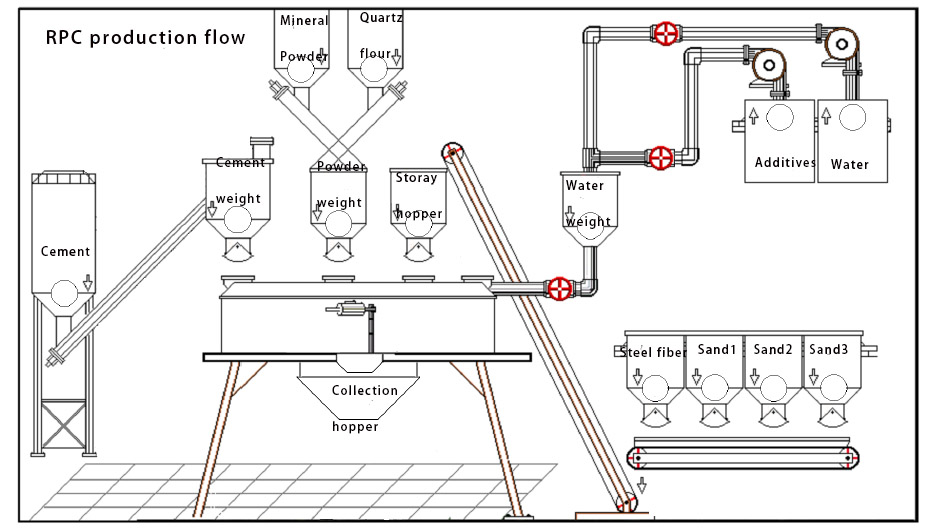

Production process:

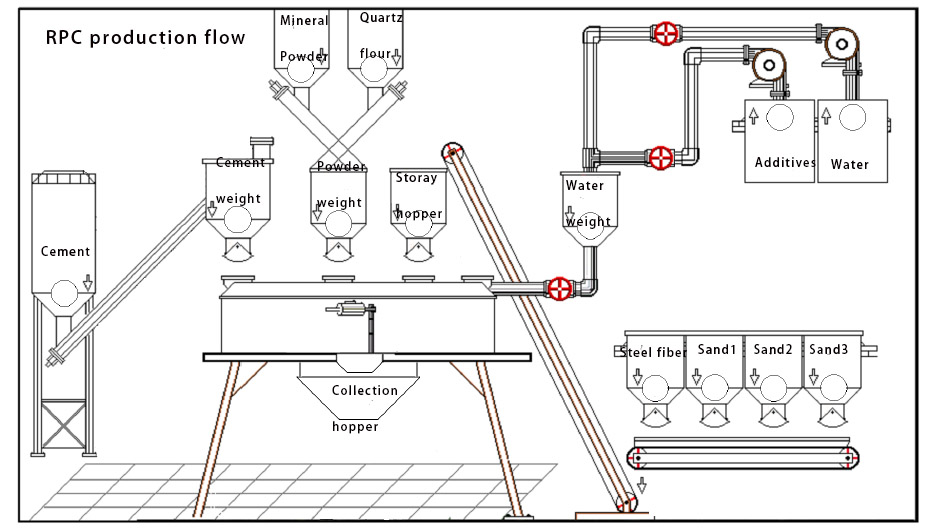

RPC board is made of high-strength cement, quartz powder and siliceous material (mainly composed of SiO2) and admixtures, with a proper amount of copper-plated steel fiber or carbon fiber added as reinforcement material. Through each powder bin, liquid bin and fiber bin, the material is divided, batched, stirred and transported to the assembly line to enter the mold box (template) for vibration, rolled and then molded at a constant temperature of 40 degrees and steamed at 80 degrees or above A new type of material with high pressure, high strength, high toughness, excellent weather resistance, impermeability and heat insulation is made by pressing curing, drying, sorting, warehousing and other processes.

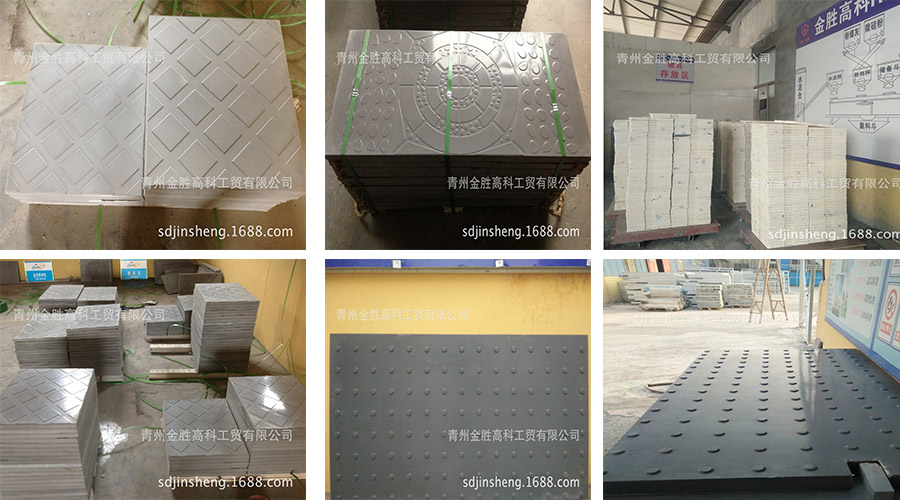

High quality RPC:

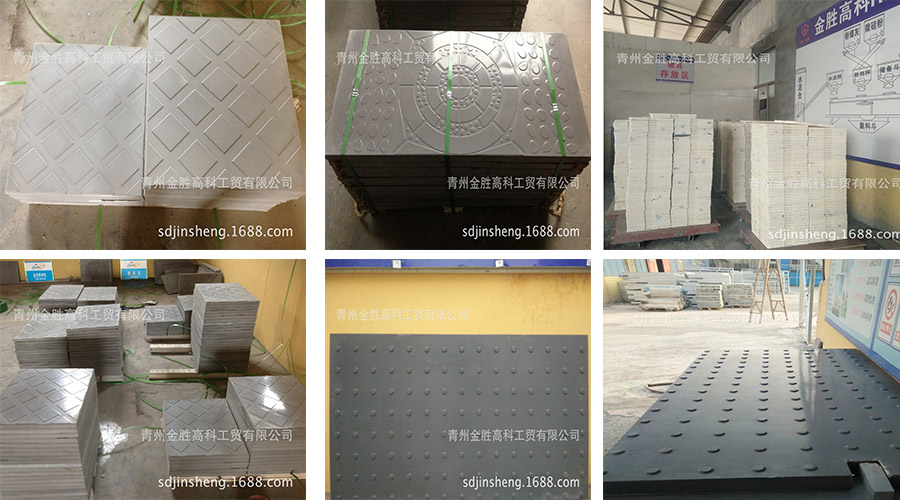

RPC board is different from the traditional cement board production, it has higher requirements for technical formula and production equipment. The production of high quality RPC board depends on the quality of raw materials, process formula, advanced production equipment and management experience. The product can be sawed, drilled, nailed, planed and other processing. The surface of RPC board can be processed with concave convex anti-skid decorative pattern by die box design. It can be widely used in construction engineering such as power plant, high-speed railway, intercity railway, subway bridge and tunnel, municipal engineering trench cover plate, cable trench cover plate, such as steel structure of construction engineering, interior wall enclosure of wood structure building, floor partition plate and sports , sound absorption board of theater and meeting room, stair pedal, etc.

Advantages of Jinsheng RPC Cover plate

1. High

strength

2. Steady

physical performance: 60 times Freezing thawing experiment without any

changing

3. Durable

save cost for curing and replacing

4. Light

weight: less thickness can reach same performance with traditional cover plate

5. Fireproof

6. Dump

proof

7. Easily

modeling

The RPC cover plate often be used for covering the drain water draintage ditch or cable trench of the railway, Municipal engineering and evacution platform.

RPC cover plate production line